Lotte Chemical Corporation

In 2011, LOTTE Chemical ed water treatment technology as a next-generation growth enginestarted to

develop technologies. We have acquired world-class water treatment membrane technology through continuous

development of wastewater treatmentwater reuse. LOTTE Chemical strives to become a global chemical

company that thinks of improving the value of lifeharmony with the environment.

- CEOShin Dong-bin, Kim Gyo-hyun, Lee Young-jun

- Line of Business Petrochemical industry

- Date of establishment 1976.03.16

- Tel+82-31-596-3114

- Fax+82-31-596-3199

- Address

- E-mailMembrane@lottechem.com

- HomePagehttps://www.lottechem.com

Introduction of Technology & Product

- UF Membrane Module

-

-

- Production of excellent quality treated water with 0.03 micrometer

(㎛) nominal pore diameter

- Pollution resistance acquired by using PVDF material, which has high

chemical resistance

- Produced in cutting-edge facilities to ensure excellent and uniform

quality hollow ber membrane

Water permeability : >400 LMH/bar Material : PVDF

Tensile : >40 kgf/ l Type : Hollow ber membrane

Applied Temperature : 1~40℃ I.D/O.D : 0.8 / 2.1mm

Applied pH : 2~10.5 Nominal pore size : 0.03㎛

-

- Production of excellent quality treated water with 0.03 micrometer

- Cassette (SHC Series)

-

-

- Low-energy, high integrated cassette

· Minimized operating pressure loss through an optimized flow design

· Improved membrane integration by e cient layout of cassette

components

- Aerators with optimized aeration e ciency

· Reduced maintenance cost by generating large air bubbles with

small air volume and maximizing cleaning effect

· Effective physical cleaning and stable operation even in high

integration of membrane modules

? we had cassette product line with various standards and membrane surface areas

-

- Low-energy, high integrated cassette

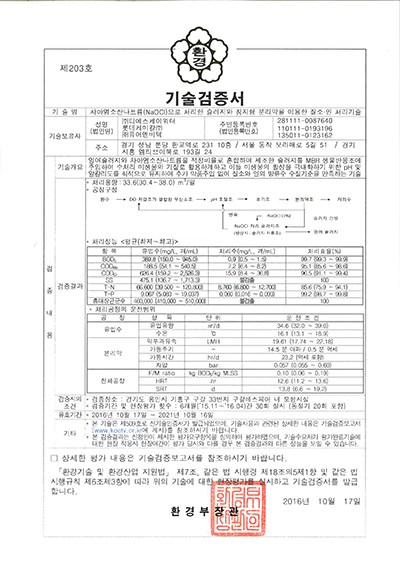

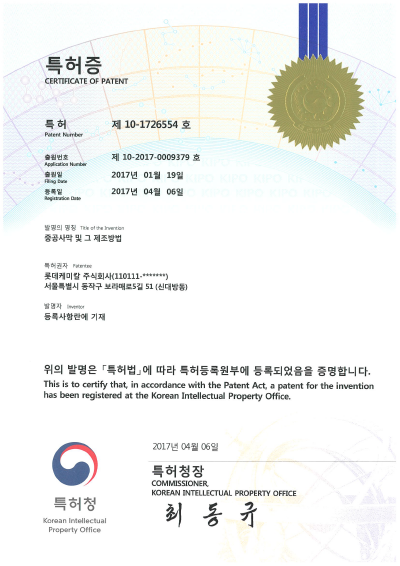

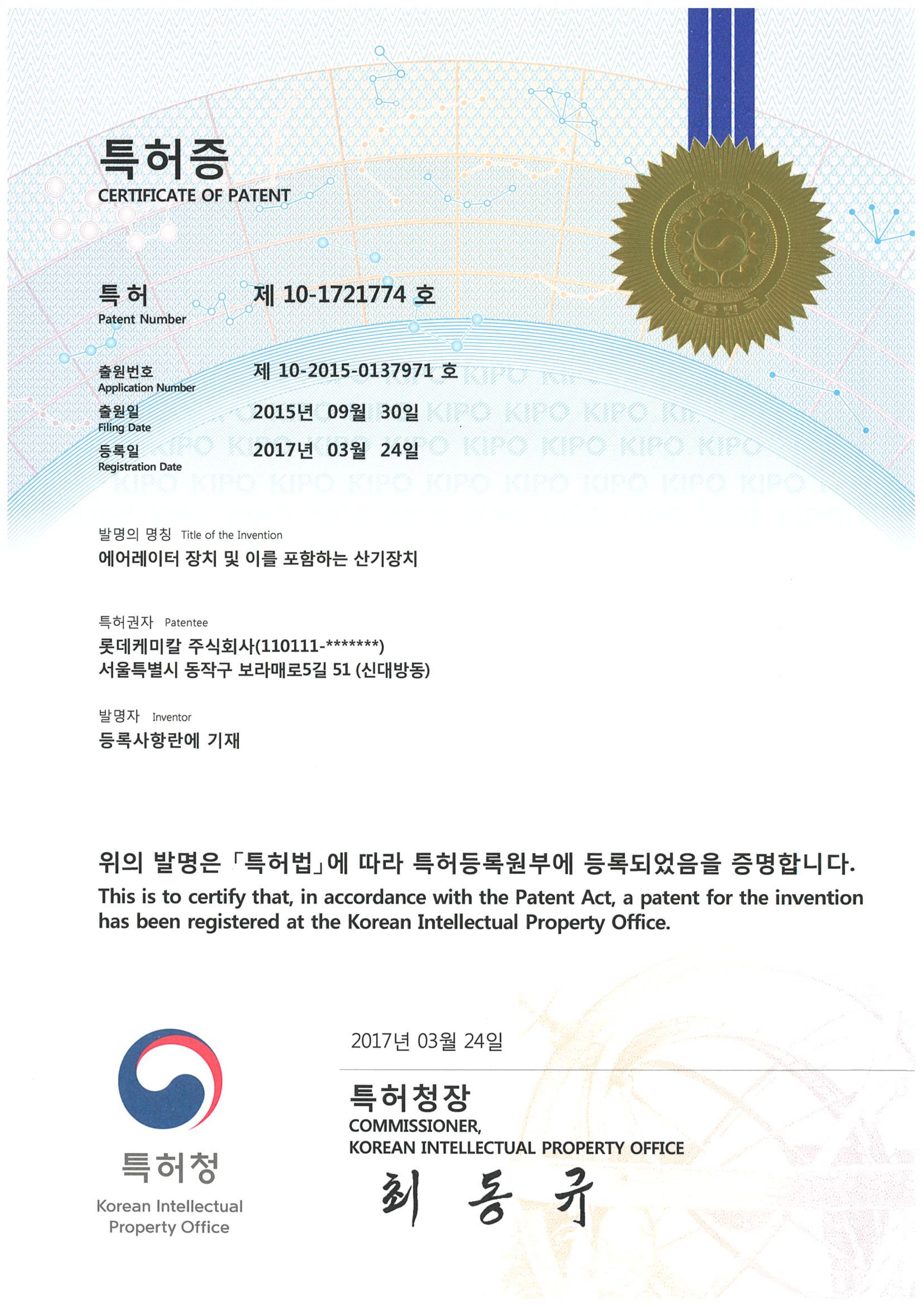

Chief authentification

Nitrogen and phosphorus treatment technology using sludge treated with sodium hypochlorite (NaOCl) and Submerged membrane system

Porous Hollow Fiber And Manufacturing Method Same

Hollow Fiber Membrane And Method For Preparing Thereof

Composition For Separation Membrane, Method For Separation Membrane Using The Same, Separation Membrane Prepared Therefrom And Apparatus For Purifying Water

Aeration Box And Diffuser Comprising The Same